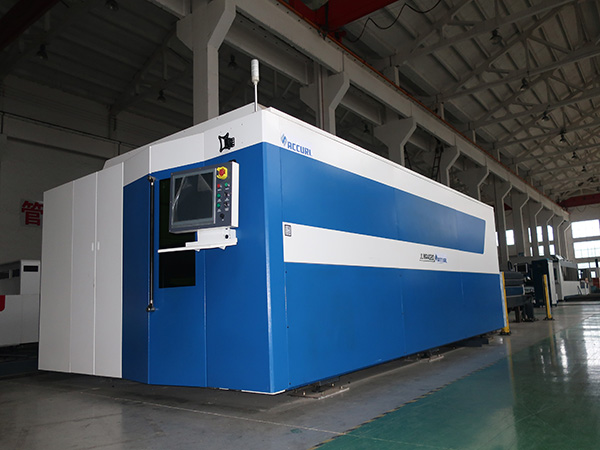

Specifications

Cutting Area: 1500*3000

Cutting Speed: 15m/min

Graphic Format Supported: DWG, LAS, DXP

Application: Laser Cutting

Condition: New

Cutting Thickness: 1-30mm

CNC or Not: Yes

Cooling Mode: Water Cooling

Control Software: CYPCUT

Place of Origin: China

Certification: CE, ISO, SGS, CCC

Warranty: More than 5 Years

Product name: laser cutting machine

Function: Cutting Metal Materials

Working area: 1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

Laser source: Germany IPG Fiber Laser

Driving system: Servo Motor

Laser head: Raytools

Compatible software: CorelDraw AutoCAD Photoshop

Positioning Accuracy: 0.01mm

Cooling system: Constant Temperature Water Chiller

Product Application

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries:Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Working Table

1. High precision CNC fixed working table

2. Special designed small pneumatic wheel carriers ,the metal sheet to be cut may slide along the machine body for easy loading

3.Strip working table; Al material,put cutting sheet on it

Fiber Laser Generator

1. Fiber Laser Module

2. Low Energy Consumption: Save energy and protect environment

3. Photoelectric conversion rate is up to 25-30%

4. Low electric power consumption, it is only about 20%-30% of traditional CO2 fiber laser cutting machine 100w

5. Lifetime is more than 100,000 hours

6.Almost free maintenance

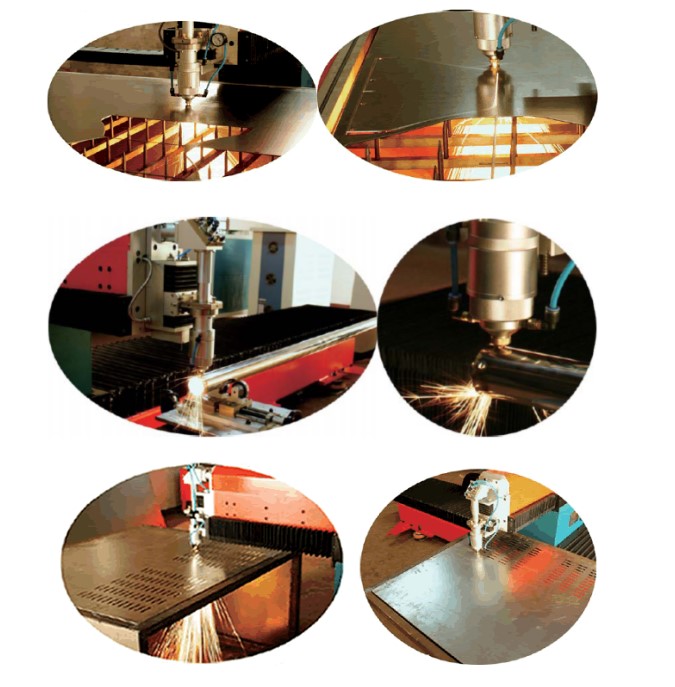

Optical System

1. Fiber transmission, no need to adjust reflect mirrors, optical path and laser source

2.Laser beam is fixed and only focused by one focus mirror to the cutting material surface

Automatic Focusing Height Follower:

1.USA improved technology and adopt China patents, automatic sensor senses the capacitance from the tip of the isolated cutting nozzle to the metal being cut. This data is then fed into the Height Follower Controller

2.If the metal sheet have wavy surfaces, the focus height follower can ensure constant distance between the focal lens and the plane of the metal sheets to be cut, so that consistent cutting quality can be achieved

3.It can avoid defects caused by wavy metal surfaces and also avoid the damage of the nozzle head.

Laser Head With Anti-Crash Function, Good sealed, high pressure resistant, auto-tracking system and anti-crash and stop system can protect good cutting quality and longer the life of lens

Drive System

1. Schneider servo motor system (made in France) ensures the possibility of realizing extreme precise positioning with the excellent dynamic response acceleration property and closed loop control method, and that makes moving positioning mechanism operate smoothly, reliably and free of maintenance

2. Servo motors in X,Y,Z, Rotary axis

3. Location accuracy: ≤±0.04mm

Application of machine