Specifications

Cutting Area:3000mm*1500mm

Cutting Speed:30m/min

Graphic Format Supported:AI, PLT, DXF, BMP, DST, DWG, LAS, DXP

Application:Laser Cutting

Condition:New

Cutting Thickness:Materials

CNC or Not:Yes

Cooling Mode:Water Cooling

Control Software:Shanghai Cypcut

Place of Origin:Anhui, China (Mainland)

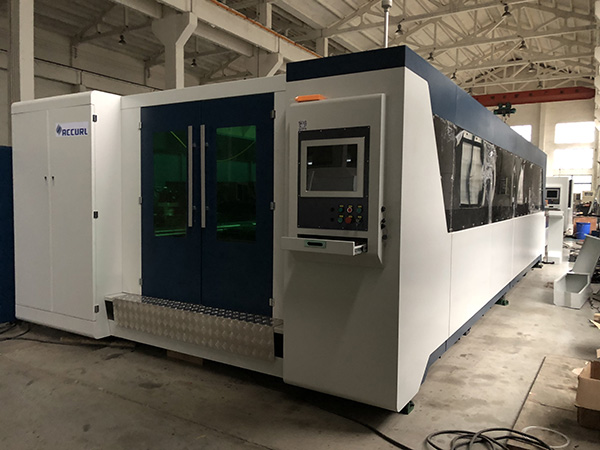

Brand Name:ACCURL

Certification:CE, ISO, SGS, UL, CCC

Warranty:2 Years, 10 years machine structure

Power mode:Fiber

Lathe bed:Plate welded structure

Cast aluminum beam:High accuracy&Easy installation

Auto lubrication system:Free of maintenance

High precision:Ensure cutting quality

Laser cutting head:US IPG /Raycus

Work life:100k hours

Guarantee:2 years for main parts

Cutting speed:0-35m/min

Product Description

Product Application

bottom price laser cutting machine 1000w 1000w with wifi wireless control

Metal Laser Cutting Machine is equipped with the most advanced international imported fiber laser source which generates powerful laser focused on objects to cause instant melting and evaporation. Automatic cutting is controlled by digitalized mechanic system. This hi-tech machine has condensed the advanced technologies of fiber laser, digital,and precise mechanics.

Laser Cutting Machine Metal Technical Parameters

Working Area | 1500X3000mm |

Laser Output Power | 500w-4000w |

Applicable Material | medium thickness metal sheet |

Laser Wavelength | 1070nm+10nm |

Cutting Thickness | ≤16mm |

Maximum Travel Speed | 60m/min |

Maximum Cutting Speed | 30m/min |

Positioning Accuracy | ±0.05mm |

Laser Wavelength | 1070nm+10nm |

Laser Cutting Machine Metal Main Features

(1) Very low cost, every hour only consumed 0.5W to 1.5W electricity, cutting all kinds of sheet metal by air;

(2) Imported original fiber lasers, High and stable function, lifespan is over 100,000 hours;

(3) Higher cutting speed and efficient, speed of cutting plate can reach over 10 meters Laser free maintenance;

(4) Smooth and fine edge or surface and small distortion;

(5)Imported servo motor and gearing system to guarantee precise cutting;

(6)Dedicated software enables graphic or text to instantly designed or processed. Flexible and easy operation.

Detailed Images

Without manual focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Bigger adjustment range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Long service life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

1.Direct control of all the fiber laser functions; Synchronized control of the laser source;

2. High speed perforation

3. Cutting data library;

4. More than 100,000 hours work-life of pumped diode,almost free maintenance.

To maintain stability: – All steel raw material is annealed to release the inner stress. – The bed is vibrated till the stress is relieved to be qualified.

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

High strength, stability, tensile strength, ensuring 20 years of use without distortion;

Thickness of rectangular pipe wall is 10mm,and weights 4500 kg.

Guide Rail

1. Wear resisting

2. Higher speed and Stable performance

3. Noise volume is lower

4. High accuracy and long service life

FAQ

1.Q:Are you trading company or manufacturer?

A: a laser machinery manufacturer dedicated to laser machinery production and concentrates innovation and R&D in laser machines.

2. Q: There are so many machine types, which one should I choose?

A: provides machine parameters in each product demo page, please kindly check technical data column. It is important to compare all data before choose the best prototype. Also, our sales team provides online services to resolve your confusion, feel free to contact us.

3.Q: I am looking for fiber laser cutting machine 1000w, any recommendation?

A: Hi, there. Thank you for your concern about our laser cutting machine 1000w. It's essential to mention us about your cutting requests (materials, thickness, application and your expectation), our sales experts provides customized consulting service in term of your demand.

4. Q:When I got this CNC Laser cutting machine meta/ fiber laser and metal laser cutting machine 1000w, but I don't know how to use it. What should I do?

A: We will send video and English manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.

5.Before sending me an inquiry on our fiber laser, it is better for you to provide me the following information

1)Your metal or non-metal material size. Because in our factory, we have different models according to working area.

2)Your materials.

Metal/Acrylic/plywood/MDF?

3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.