Specifications

Cutting Speed:80m/min

Graphic Format Supported:DWG, DXF

Application:Laser Cutting

Condition:New

Cutting Thickness:0-25mm

CNC or Not:Yes

Cooling Mode:Water Cooling

Control Software:Cypcut

Place of Origin:China Anhui (Mainland)

Brand Name:ACCURL

Certification:CE, ISO, SGS

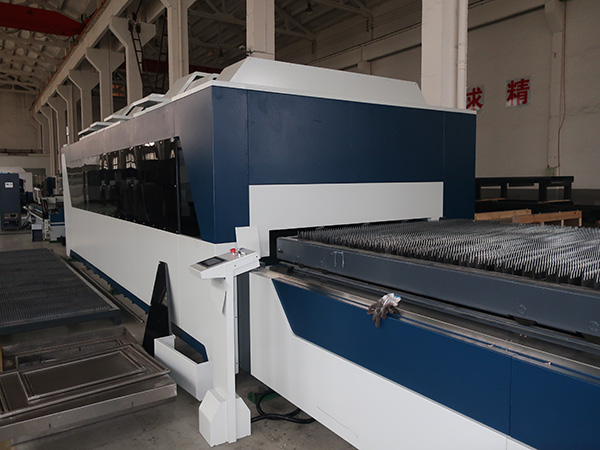

Product name:Fiber Laser Tube & Plate cutter

Power supply:5000W/700W/750W/800W/1000W/1200W/2000W

cutting shape:plate and pipe

Working area:1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

Type:Fiber Lasr Cutting

Max position speed:80m/min

Tube cuting diameter:30mm-220mm

Tube cutting length:Less than 6m

X,Y axis position accucy:0.05mm

X,Y axis repeatability accuracy:0.025mm

After-sales Service Provided:Engineers available to service machinery overseas

Advantages of Fiber laser cutting machine:

1. Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2. High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7 Easy operations: fiber line transmission, no adjustment of optical path.

Technical Parameters

Effective working area (mm) | 3000x1500/4000x2000/6000x2000 | ||

Max pipe diameter | 200mm(can be customized by 600mm) | ||

Pipe length | 6mm | ||

Z axis stroke | 120 mm | ||

Max position speed | 60 m/min | ||

X,Y axis position accuracy | 0.05 mm | ||

X,Y repeatability accuracy | 0.025 mm | ||

Laser Source | 500w/700w/750w/800w/1000w/1200w/2000w | ||

Carbon steel | ≤10mm | ||

Stainless steel | ≤ 4mm | ||

Aluminum | ≤ 4mm | ||

Standard configuration

Fiber power supply | Raycus/IPG | ||

Fiber cutting head | Raytool | ||

Machine body | TAYOR | ||

Cross Beam | TAYOR | ||

Working table | TAYOR | ||

Gear box | Apex | ||

X,Y Rack and pinion | Sweden Linden | ||

Ball screw | Taiwan Hiwin | ||

rail | Taiwan Hiwin | ||

Pneumatic system | Japan SMC | ||

cooling system | Tayor | ||

Electrical components | Schneider | ||

Control system | CypCut | ||

AC servo motor and driver | Yaskawa | ||

CAD/CAM software | Smart Nest professional | ||

Cutting parameter(700w laser power in case)

Laser power(W) | Material | Thickness(mm) | Speed(m/min) | Cutting gas |

700W | Stainless steel | 0.5 | 21 | N2 |

1 | 16 | N2 | ||

2 | 5 | N2 | ||

3 | 2 | N2 | ||

4 | 1.2 | N2 | ||

700W | Carbon steel | 1 | 12 | O2 |

2 | 6 | O2 | ||

3 | 4 | O2 | ||

4 | 3 | O2 | ||

5 | 2 | O2 |

Total electricity cost

Items | Power(kw) | Total Power(kw/h) | Total cost(usd/h) |

Laser | 2.9 | ≦20.9 | USD2.0 (Accounts for 60% total load) |

machine | 9.5 | ||

chiller | 4.5 | ||

Air compressor | 4 |

Gas cost

Gas type | Price (USD/cylinder) | Capacity(Min/cylinder) | Cost(USD/H) | Remark |

O2 | 2.5 | 60 | 2.5 | 1mm carbon steel |

N2 | 4.2 | 15 | 16.5 | 1mm carbon steel |

Liquid N2 | 55 | 120 | 4.5 | 1mm stainless steel |

Air | 1.1(air compressor) | with Less than 2mm carbon steel, quality cutting |

Installation terms

Seller personnel will supervise installation as following:

1) installation and assembly

2) Positioning of machine and the work table

3) Running of cables and hoses from service entry point

4) Connection of electrical cables and gas hoses to the machine

Training terms

After the commissioning, Seller technician will commence Training.

The customer shall provide sufficient material and consumables to ensure satisfactory completion to training.

The training will comprise of the following things:

1) Overview of machine

2) Control features and operation

3) Machine maintenance and adjustment

4) Supervised running of machine

The training of the machine operator is concurrent with the installation and commissioning, therefore personnel must be available at all times.