Specifications

Cutting Speed:0-60m/min

Graphic Format Supported:AI, DWG, DXF, PLT, Other

Application:Laser Cutting

Condition:New

Cutting Thickness:0-30mm

CNC or Not:Yes

Cooling Mode:Water Cooling

Control Software:Cypcut,FSCUT2000,Cypnest

Place of Origin:Anhui, China (Mainland)

Certification:CE, SGS

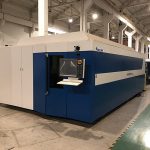

Product Name:fiber laser cutting machine

Laser Power:700W-10000W

Drive Type:Servo motor and drive

Control:CNC

Max Moving Speed:100m/min

Power Allocation:380V/220V±10%, 50Hz/60Hz

Continuous Working Time:24 hours

Weight of Machine:Approx: 8 Tons

Machine Size (l*w*h):8.5*3.3*1.9m

After-sales Service Provided:Overseas service center available

Product Detail

| Product Name | fiber laser cutting machine |

| Laser Power | 700W-10000W |

| Laser Type | Fiber Laser |

| Drive Type | Servo motor and drive |

| Control | CNC |

| Max Moving Speed | 100m/min |

| Power Allocation | 380V/220V±10%, 50Hz/60Hz |

| Continuous Working Time | 24 hours |

| Weight of Machine | Approx: 8 Tons |

| Machine Size (l*w*h) | 8.5*3.3*1.9m |

| Product Keywords | 5 axis laser cutting |

1. The whole machine is fully enclosed to reduce laser radiation and prevent mechanical damage.

2. Exchange worktable, save loading and unloading time, and improve work efficiency

3. High-precision grinding grade gears, racks, low noise, high precision and fast speed

4.SMC pneumatic components, intelligent control, perfect low pressure perforation

5. High-strength integral welding body, cast aluminum X axis and high temperature annealing to ensure that the machine tool will not be deformed after 20 years of normal use.

6. It is driven by world class precision ball screw/rack and linear guide to achieve high precision, high efficiency and stability of the machine.

7. Equipped with the most advanced wireless handheld terminal for remote processing device

8. The equipment adopts high-performance numerical control system, AC servo motor and drive. It is a integrating advanced technologies such as pneumatic, mechanical, optoelectronic and numerical control.

FAQ

What is Laser Cutting?

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications,Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

How this Fiber Laser cut in Metal?

Very good, we can say the fiber laser is born for metal cutting because metal have high absorption rate of fiber laser, and it is cost of running much lower than high power Co2 laser.

What materials can be cut by this Fiber Laser Cutting Machine?

Most of the fabricator use it to cut Stainless steel, Carbon Steel, Mild Steel, Iron, galvanized steel, sometimes they cut Aluminum and brass too, And some customer uses it to cut gold, silver for jewelry production.

What is the thickness the machine can cut?

We would like to say different power source can cut different thickness material, it is related to material and gas pressure. for example, 1kw IPG laser source max cut 12mm CS, and 5mm SS, for details please write us for a table sheet of material, laser power, speed, gas etc.

How many options of laser source? What are the differences?

Normally we offer IPG, RAYCUS, MAX, differences is the cost and the cutting quality, we have experi

which operating software would be used in your machine?

Priority option is Cypcut controller, Economic cost and great performance, But we the other options are available.